Elevating Lift Maintenance: Best Practices for Lift Businesses

Introduction:

Proper lift maintenance is crucial for ensuring safe and efficient

operations in the lift industry. In countries, where elevators play a vital role in various

sectors such as commercial buildings, residential complexes, and industrial facilities, it

is essential for businesses to implement effective maintenance strategies to meet the high

demands of lift usage. This blog aims to provide valuable insights into lift maintenance

best practices, offering tips and guidelines specifically tailored to, lift and elevator

businesses.

Lift businesses face unique challenges due to factors such as extreme

weather conditions, high usage rates, and stringent safety regulations. By adopting the

right maintenance strategies, businesses can optimize lift performance, enhance user safety,

and extend the lifespan of their equipment.

Throughout this blog, we will explore various aspects of lift

maintenance, including effective strategies, practical tips, and essential guidelines.

Importance of Regular Inspections

Regular inspections are of paramount importance in lift maintenance as

they ensure the safety, functionality, and compliance of lift systems. Inspections play a

crucial role in identifying potential safety hazards and ensuring the safe operation of

lifts. By conducting regular inspections, lift businesses can detect issues such as worn-out

components, loose connections, faulty safety devices, or improper functioning of emergency

systems.

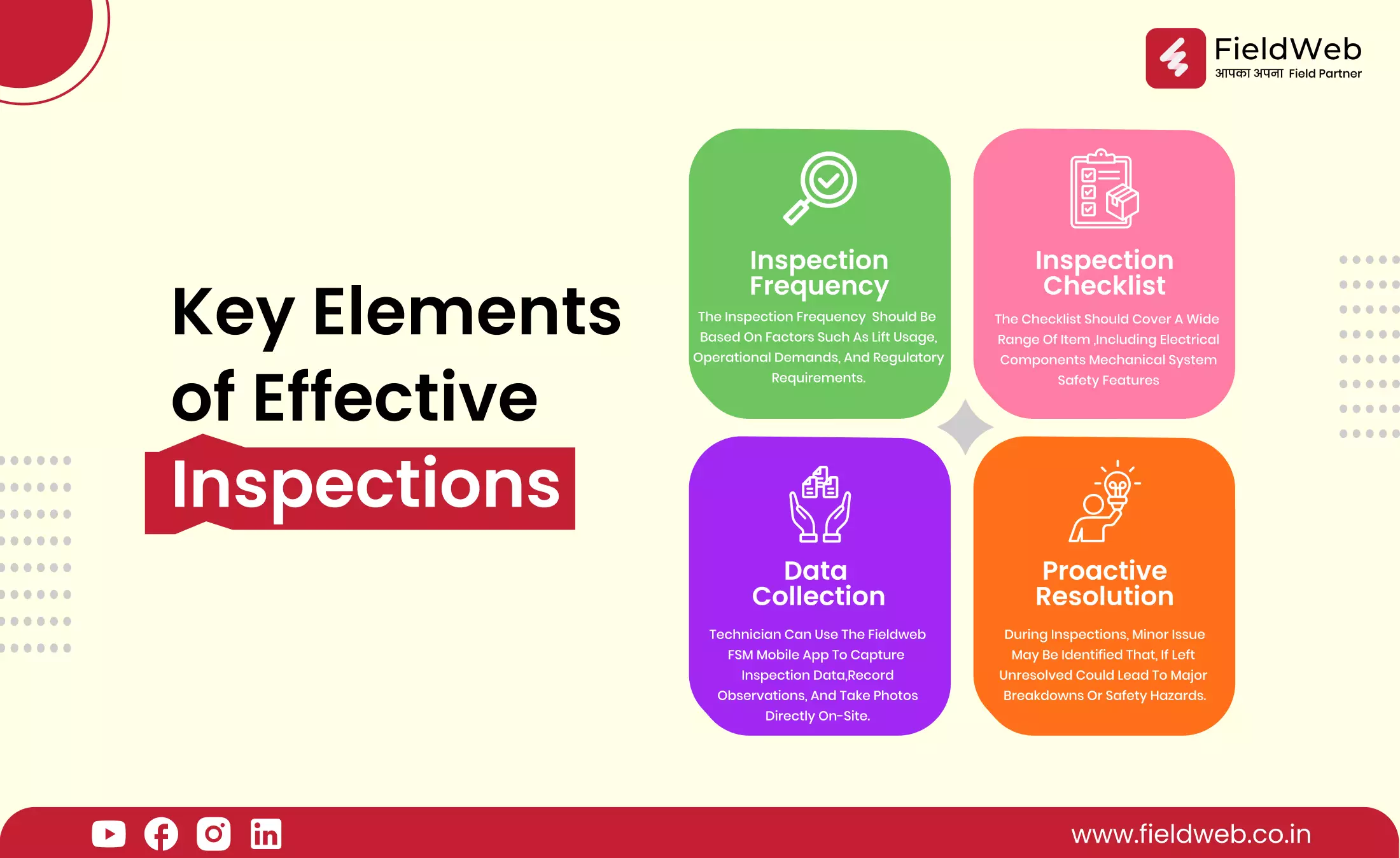

Key Elements of Effective Inspections

- Inspection Frequency: Determining the appropriate frequency of inspections is

crucial for maintaining lift safety and performance. The inspection frequency should be

based on factors such as lift usage, operational demands, and regulatory requirements.

Lift businesses should consider the volume of daily usage, the type of building or

facility where the lifts are installed, and any specific regulations or standards

applicable to their industry.

- Inspection Checklist: Creating a comprehensive inspection checklist is essential

to ensure that all essential components and systems are thoroughly inspected. The

checklist should cover a wide range of items, including electrical components,

mechanical systems, safety features, and emergency procedures.

- Data Collection and Reporting:Digital tools like FieldWeb-FSM can significantly

streamline the data collection and reporting process during inspections. Technicians can

use the FieldWeb-FSM mobile app to capture inspection data, record observations, and

take photos directly on-site. This eliminates the need for manual paperwork and ensures

accurate and consistent data collection.

- Proactive Issue Resolution: During inspections, minor issues may be identified

that, if left unresolved, could lead to major breakdowns or safety hazards. Lift

businesses should prioritize the prompt resolution of these issues to prevent more

significant problems from arising. FieldWeb-FSM can facilitate proactive issue

resolution by providing a platform for technicians to report and document identified

issues.

The Role of Preventive Maintenance

Preventive maintenance plays a vital role in ensuring the reliability,

safety, and longevity of lift systems. By implementing a proactive approach to maintenance,

lift businesses can minimize unexpected breakdowns, reduce downtime, and optimize the

performance of their lifts.

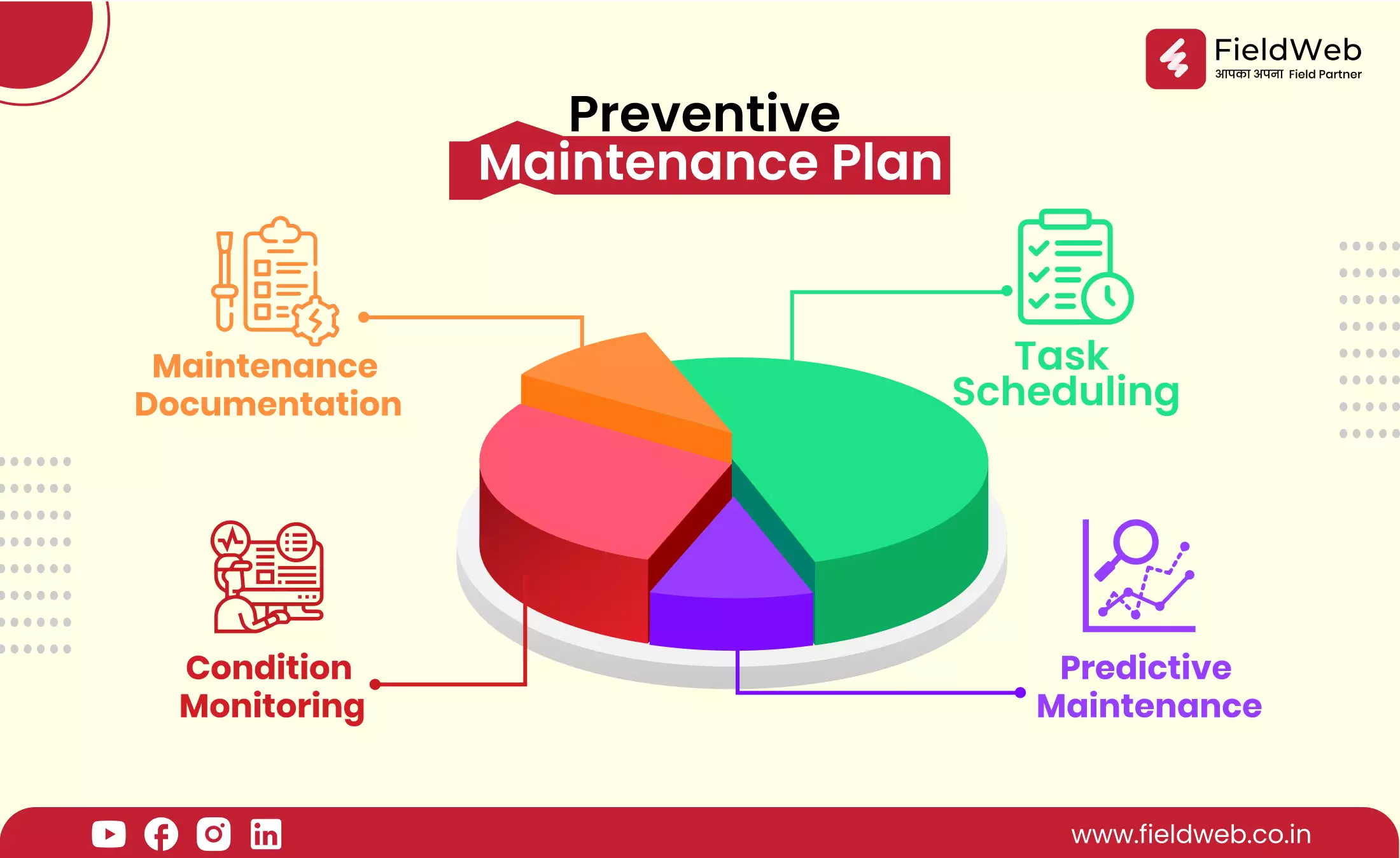

Developing a Preventive Maintenance Plan

- Task Scheduling: Effective task scheduling is crucial for lift maintenance to

ensure that routine maintenance tasks are performed in a timely manner. Lift businesses

should create a schedule for tasks such as lubrication, adjustment, and component

replacement. By adhering to a predefined schedule, businesses can prevent potential

issues, extend the lifespan of lift equipment, and minimize unexpected downtime.

- Condition Monitoring: Condition monitoring involves the use of advanced

technologies and sensors to monitor the performance of lifts continuously. These

technologies can detect early signs of potential issues, such as abnormal vibrations,

temperature variations, or deviations in operating parameters. By monitoring lift

performance, businesses can identify problems at an early stage and take proactive

measures to address them, minimizing the risk of breakdowns and costly repairs.

- Predictive Maintenance: Predictive maintenance goes beyond traditional preventive

maintenance approaches by leveraging data collected through condition monitoring. By

analyzing the collected data, businesses can identify patterns, trends, and anomalies

that may indicate potential maintenance needs. This enables lift businesses to predict

when maintenance or repairs will be required and schedule proactive maintenance

activities accordingly.

- Maintenance Documentation: Accurate and comprehensive maintenance documentation

is crucial for lift businesses. FieldWeb-FSM can serve as a powerful tool for recording

maintenance activities, tracking maintenance history, and automating maintenance

reminders. The system allows technicians to log detailed information about each

maintenance task, including the date, time, performed activities, and any parts used.

Adhering to Safety Standards and Regulations

Adhering to safety standards and regulations is of utmost importance in

the lift industry to ensure the safety and well-being of passengers and maintain compliance

with legal requirements. Lift businesses in must prioritize the adherence to established

safety standards and regulations set by local authorities and industry organizations. By

complying with these standards, businesses demonstrate their commitment to maintaining safe

lift operations and safeguarding the welfare of users.

Staff Training and Education

- Technical Training: To ensure the highest level of lift maintenance, it is

essential to provide comprehensive training programs to technicians. These training

programs should focus on equipping technicians with up-to-date knowledge of lift

technologies and maintenance procedures. FieldWeb-FSM can play a vital role in

supporting technical training initiatives by providing a centralized platform for

training materials, resources, and documentation.

- Safety Protocol: Safety is of paramount importance in lift maintenance. It is

crucial to educate maintenance staff about safety protocols, emergency procedures, and

risk prevention measures. Technicians should be well-versed in safety standards and

regulations specific to the lift industry.

- Continuous Learning: The lift industry is continually evolving, with new

technologies and best practices emerging. Encouraging technicians to engage in

continuous learning is vital for staying updated with industry advancements and

improving their skills.

- Documentation and Certifications: Effective documentation and certifications are

essential in lift maintenance to ensure compliance, track progress, and facilitate

knowledge sharing within the organization. Standard Operating Procedures (SOPs) should

be developed to outline maintenance procedures, safety protocols, and best practices.

Condition Monitoring and Predictive Maintenance

Condition monitoring and predictive maintenance are essential components

of a proactive lift maintenance strategy. In countries, where lift systems experience high

usage and are subject to various environmental factors, implementing condition monitoring

and predictive maintenance techniques can significantly enhance lift performance and

minimize unexpected breakdowns.

Condition monitoring involves the use of advanced technologies and

sensors to continuously monitor the operating parameters of lifts. By collecting real-time

data on factors such as vibration, temperature, and energy consumption, technicians can gain

valuable insights into the condition of lift components and detect early signs of potential

issues. This proactive approach allows for timely intervention before minor problems

escalate into major failures.

Integration of FieldWeb-FSM for Streamlined Maintenance

- Asset Tracking and Management: Asset tracking and management are critical

components of any lift maintenance strategy. FieldWeb-FSM provides robust asset tracking

and management capabilities, allowing businesses to keep track of all their assets,

manage inventory, and ensure proper maintenance of spare parts.

- Work Order Management: FieldWeb-FSM provides a comprehensive work order

management system that streamlines work order creation, assignment, and tracking. The

system allows businesses to create work orders quickly and easily, assign them to

technicians based on their skill sets and availability, and track the progress of each

work order in real-time. This helps businesses ensure that all work orders are completed

on time and to the required standards.

- Mobile-enabled Inspections: FieldWeb-FSM's mobile app allows technicians to

conduct inspections, capture data, and generate reports on the go. This makes it easy

for businesses to stay on top of inspections and maintenance tasks, even when

technicians are working remotely. Technicians can use the app to access work orders,

view inspection checklists, and record data such as asset information, maintenance

records, and photos. This helps businesses maintain accurate and up-to-date records of

their assets and maintenance activities.

Promoting Safety Awareness and Reporting

Promoting safety awareness and fostering a culture of reporting are

vital aspects of lift and elevator maintenance. By prioritizing safety and creating an

environment where employees feel comfortable reporting potential hazards or incidents, lift

businesses can enhance safety standards and mitigate risks effectively.

One of the key elements in promoting safety awareness is conducting

regular safety meetings. These meetings serve as a platform for discussing safety-related

topics, sharing best practices, and addressing any concerns raised by the maintenance staff.

It is an opportunity to reinforce safety protocols, provide updates on industry regulations,

and discuss lessons learned from past incidents. FieldWeb-FSM can support these safety

meetings by providing a centralized platform for documenting meeting minutes, sharing safety

resources, and tracking action items to ensure timely follow-up.

Continuous Improvement and Performance Evaluation

- Safety Meetings and Training: Conducting regular safety meetings is a critical

component of effective lift maintenance strategies. These meetings serve as a platform

for discussing safety-related topics, sharing best practices, and addressing concerns.

By prioritizing safety communication and awareness, lift businesses can create a culture

of safety that permeates throughout the organization.

- Incident Reporting and Analysis: Incident reporting and analysis are critical for

identifying safety issues and implementing corrective measures. FieldWeb-FSM provides

incident reporting features that enable lift businesses to track safety incidents and

investigate their root causes. By analyzing incident data, businesses can identify

trends and areas for improvement, and take corrective action to prevent similar

incidents.

- Performance Evaluations: Assessing maintenance staff's performance is a key

component of effective lift maintenance strategies. Performance evaluations should be

based on key performance indicators (KPIs) such as maintenance completion rates,

response times, and customer satisfaction. Safety records should also be taken into

account when evaluating performance.

- Feedback and Recognition: Encouraging feedback from technicians is essential for

identifying safety issues and improving lift maintenance strategies. Technicians are

often on the front lines of lift maintenance and may have valuable insights into safety

hazards and potential risks.

Conclusion

In conclusion, implementing effective lift maintenance strategies is

crucial for lift and elevator businesses to ensure safe and reliable elevator operations. By

conducting regular inspections, prioritizing preventive maintenance, ensuring compliance

with safety standards, providing proper training, implementing condition monitoring,

leveraging technology such as FieldWeb-FSM, and fostering a culture of safety and

accountability, lift businesses can optimize their maintenance efforts. FieldWeb-FSM acts as

a comprehensive field service management solution, enabling businesses to streamline their

lift maintenance processes, enhance data collection, and improve overall efficiency.

By combining industry best practices with the capabilities of

FieldWeb-FSM, lift businesses can elevate their maintenance operations, reduce downtime,

enhance safety, and deliver a superior lift experience to their customers.