FieldWeb Blog.

Get the knowledge and inspiration you need to run your home and commercial service business better.

In the HVAC industry, regular maintenance is crucial to ensure systems operate efficiently and reliably. Traditional maintenance methods, like reactive or preventative maintenance, often fall short of providing long-term solutions. This is where predictive maintenance steps in. Powered by cutting-edge technology, predictive maintenance anticipates when equipment will fail or require servicing, allowing businesses to address issues before they cause costly breakdowns or downtime.

In this blog, we will explore the role of predictive maintenance in the HVAC industry, how it works, its key benefits, and why small to large HVAC businesses, such as Armstrong, Al-Fanoos HVAC, and Atharv Aircon, are adopting this approach to stay ahead of equipment failures.

Predictive maintenance is a proactive approach that uses data-driven insights to predict equipment failures before they happen. Unlike preventative maintenance, which schedules maintenance based on time intervals, or reactive maintenance, which occurs after equipment failure, predictive maintenance relies on real-time data to make maintenance decisions.

Sensors embedded in HVAC systems track key metrics like temperature, pressure, and airflow. This data is continuously monitored, and advanced analytics are used to detect patterns or anomalies that may indicate potential issues. Once a problem is predicted, technicians can be alerted to perform necessary repairs or maintenance, reducing the likelihood of unexpected breakdowns.

HVAC systems are complex, and their failures can have significant financial impacts, particularly in commercial settings. For example, in large office buildings, factories, or shopping malls, HVAC downtime can lead to uncomfortable conditions, energy inefficiencies, and even operational disruptions.

As HVAC systems grow in complexity, relying on outdated maintenance methods is no longer sufficient. Predictive maintenance offers a solution that not only prevents downtime but also extends the life of HVAC equipment, saving businesses substantial costs in the long run.

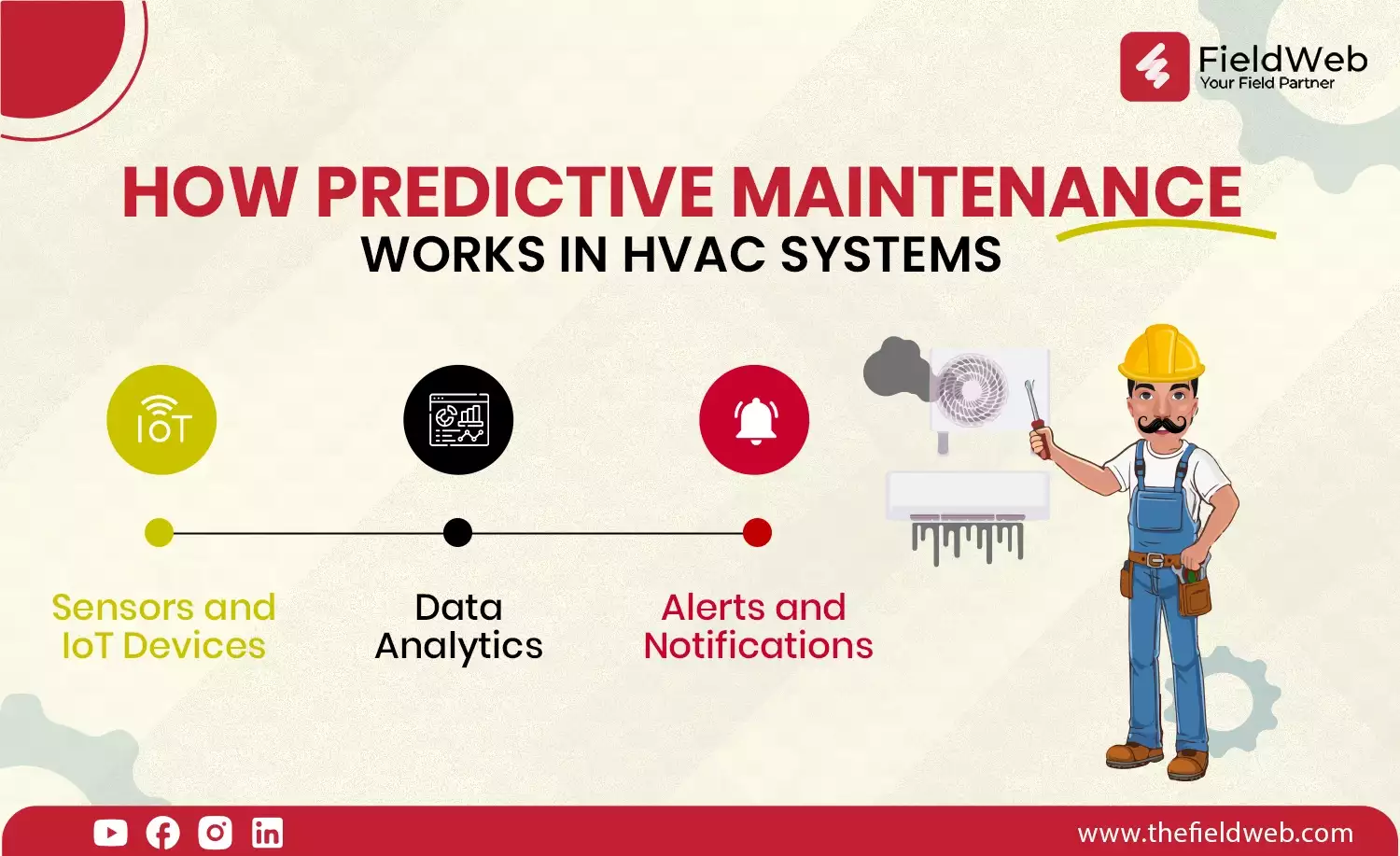

Predictive maintenance in HVAC relies on three key components: sensors, data analytics, and real-time monitoring.

Predictive maintenance begins with sensors installed in HVAC units. These sensors monitor system performance in real-time, tracking parameters such as airflow, compressor temperature, and refrigerant levels. For example, a sensor may detect a gradual decrease in airflow, signaling a potential blockage or malfunction.

The data collected from these sensors is then fed into advanced HVAC management software, like FieldWeb, which uses algorithms to analyze the data and identify patterns that may indicate future problems. This allows the system to predict when a component may fail or require servicing, sometimes weeks or months in advance.

Once the software detects an issue, it sends an alert to technicians, enabling them to perform maintenance before the issue escalates. For instance, Al-Fanoos HVAC uses predictive maintenance to automatically dispatch their technicians when the software detects irregular pressure in their HVAC systems, ensuring timely intervention.

Predictive maintenance offers numerous benefits to HVAC businesses, from reducing costs to improving customer satisfaction.

Predictive maintenance minimizes emergency repairs, which are typically more expensive than planned maintenance. It also extends the lifespan of HVAC equipment by addressing issues before they cause significant damage.

For example, Armstrong, a leading HVAC company, reported a 25% reduction in maintenance costs after implementing predictive maintenance solutions through FieldWeb.

Unexpected system failures can bring HVAC operations to a standstill, especially for commercial and industrial clients. Predictive maintenance ensures that potential issues are detected early, preventing unscheduled downtime.

A study showed that businesses implementing predictive maintenance experience 75% fewer breakdowns compared to those using reactive approaches.

Well-maintained HVAC systems operate at optimal efficiency, leading to lower energy consumption. Predictive maintenance identifies inefficiencies such as refrigerant leaks or airflow blockages before they lead to increased energy costs.

Atharv Aircon has seen an 18% reduction in energy usage across their clients after using predictive maintenance to detect refrigerant leaks early on.

HVAC companies using predictive maintenance can provide quicker, more reliable service to their clients. By avoiding sudden failures and ensuring systems run smoothly, they enhance customer trust and satisfaction.

For instance, Techno Air Track has significantly improved client retention rates by offering predictive maintenance as part of their service package, ensuring their customers experience minimal disruptions.

Predictive maintenance not only saves money and improves efficiency, but it also contributes to a more sustainable operation. Reducing energy waste and extending the life of HVAC systems helps businesses lower their environmental impact.

The success of predictive maintenance largely depends on the field service business software that collects and processes data from HVAC systems. Solutions like FieldWeb play a pivotal role in streamlining the process for businesses.

Clients such as DSI HVAC & MEP have adopted FieldWeb’s predictive maintenance solution, resulting in more streamlined operations and higher efficiency in managing their HVAC equipment.

While predictive maintenance offers many benefits, some challenges can arise during implementation, particularly for smaller HVAC businesses.

The upfront costs of installing sensors and IoT devices may be a barrier for smaller HVAC companies. However, these costs are often offset by long-term savings in maintenance and energy efficiency.

Technicians must be trained to use predictive maintenance software effectively, which can require time and resources. To overcome this, software providers like FieldWeb offer training and support to ease the transition.

Some businesses may struggle to integrate predictive maintenance software with their existing infrastructure. FieldWeb addresses this by offering seamless integration solutions that work with a wide range of HVAC systems.

The HVAC industry is rapidly evolving, and predictive maintenance is becoming a key strategy for reducing costs, improving efficiency, and enhancing customer satisfaction. By leveraging technology, HVAC businesses can ensure their systems operate reliably while minimizing downtime and maximizing energy efficiency.

Companies like Armstrong, Al-Fanoos HVAC, and Techno Air Track are already reaping the benefits of predictive maintenance with solutions like FieldWeb. For HVAC businesses looking to stay ahead of the curve, investing in predictive maintenance is no longer an option — it's a necessity.